ELECTRONIC COMPONENTS

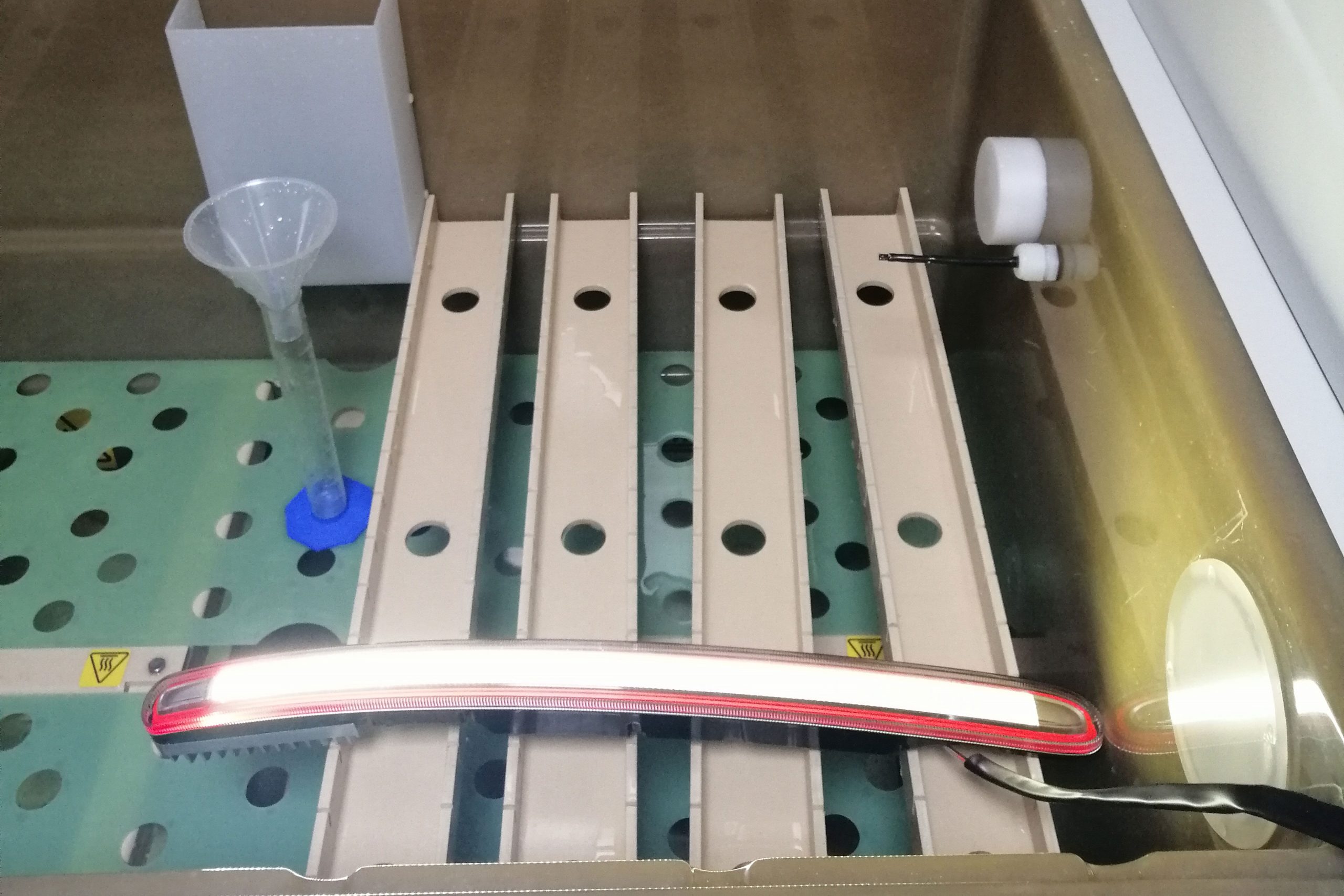

By simulating the weather conditions (heat, cold, humidity, etc.) that electronic components may encounter over time, the resistance of the components to this environmental stress is observed.

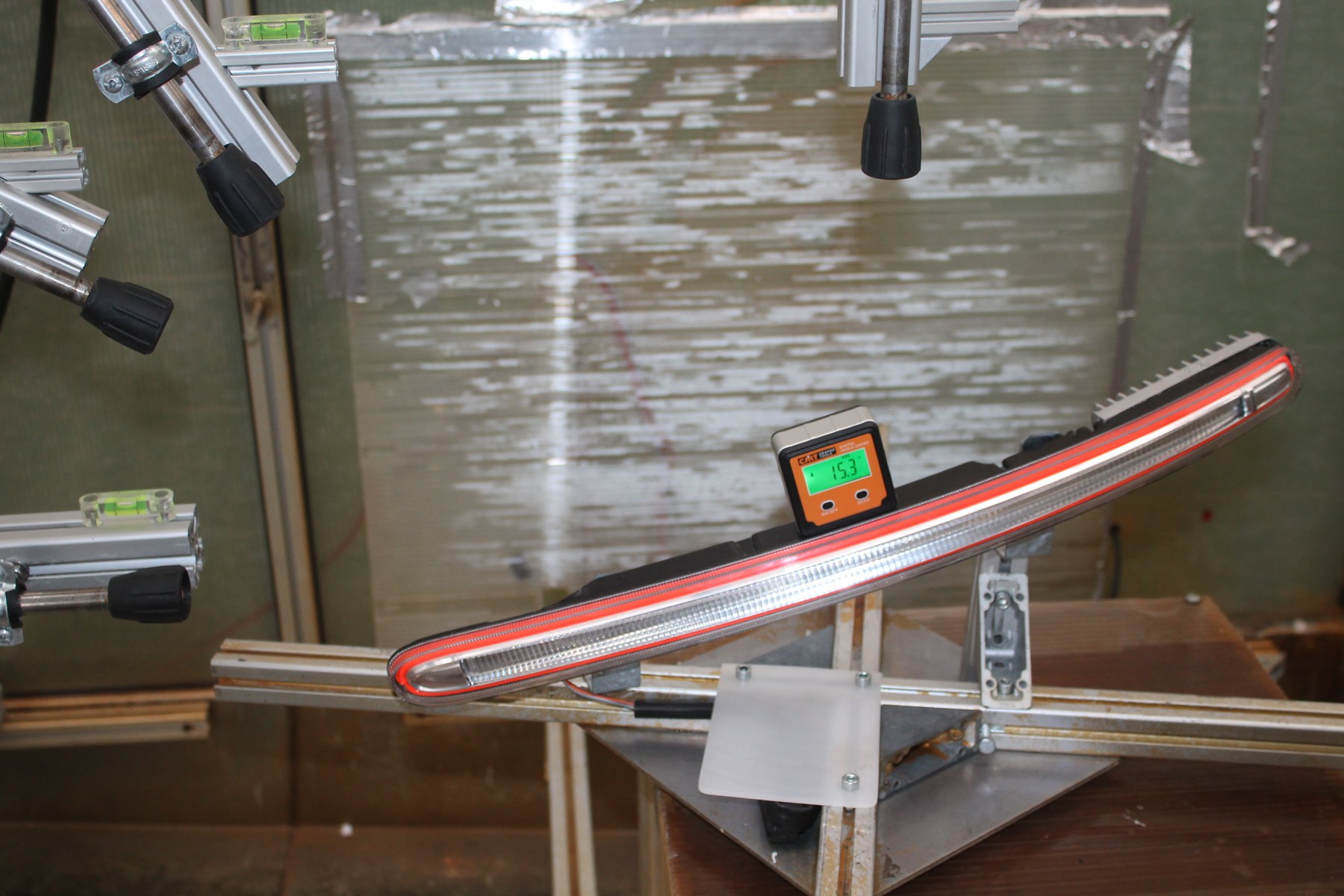

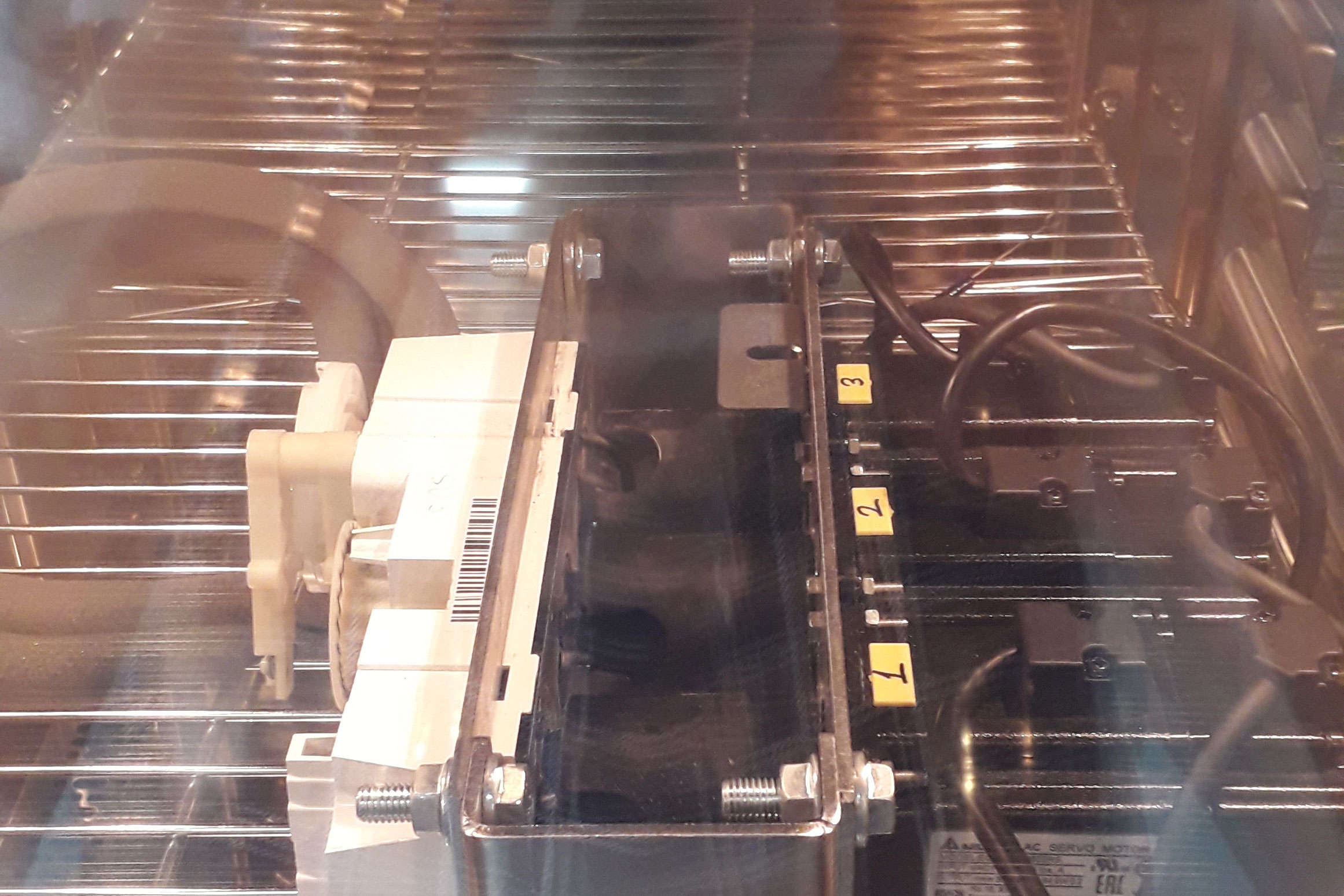

Electronic components are tested under certain frequency and temperature conditions in order to simulate the vibration factors that these will be exposed to over time and to observe the resistance of the components to these factors..

Corrosion or visible defects are investigated by spraying saline solution at a constant temperature and concentration on the surfaces of electronic components continuously or in determined cycles.

In order to observe the sudden temperature effects on electronic components, tests are applied at the number of cycles determined in thermal shock cabinets.

Electrical tests are applied in order to test the resistance of electronic components to voltage changes that may be exposed during vehicle operation or in certain failure situations.

Various tests are carried out under different pressure, temperature and flow conditions in order to simulate the effects that electronic components will be exposed to during vehicle washing.

Various tests are carried out to simulate the dust effects that electronic components may be exposed to under road conditions.

The resistance of electronic components against physical deterioration that may occur as a result of possible or long-term exposure to chemicals such as automobile liquids, cosmetics, cleaners and beverages is determined.

After the electronic components are subjected to tests under certain conditions, tests are carried out to see whether these tests affect the functionality of the component.

Effects such as opening / closing / turning that the parts may be exposed to during use are simulated with test fixtures suitable for the part.